Presentation Packaging

We have a product for all of your presentation needs, whether it’s for an exhibition, a conference or something else entirely! Make a big impact and look professional with our high quality products that we’ve perfected for over 80 years in the industry!

Product Packaging

It's so important to get the packaging right when you are trying to get your products discovered. We specialise in showcasing our clients retail products using inventive and practical Packaging Solutions.

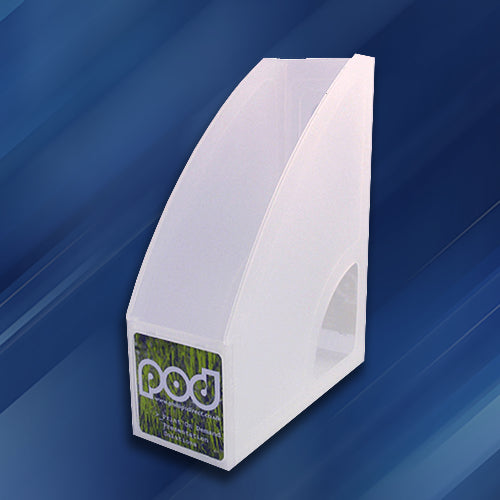

Promotional Packaging

Want to promote your business in a sustainable way? Take a look at our fantastic POD range to market your business professionally and effectively, whilst reducing the impact on the environment at the same time.

Sustainable Packaging

Are you trying to move away from using non-recyclable materials? So are we! Our design team are passionate about taking your designs and redesigning them using sustainable and fully recyclable materials, to reduce our carbon footprint.

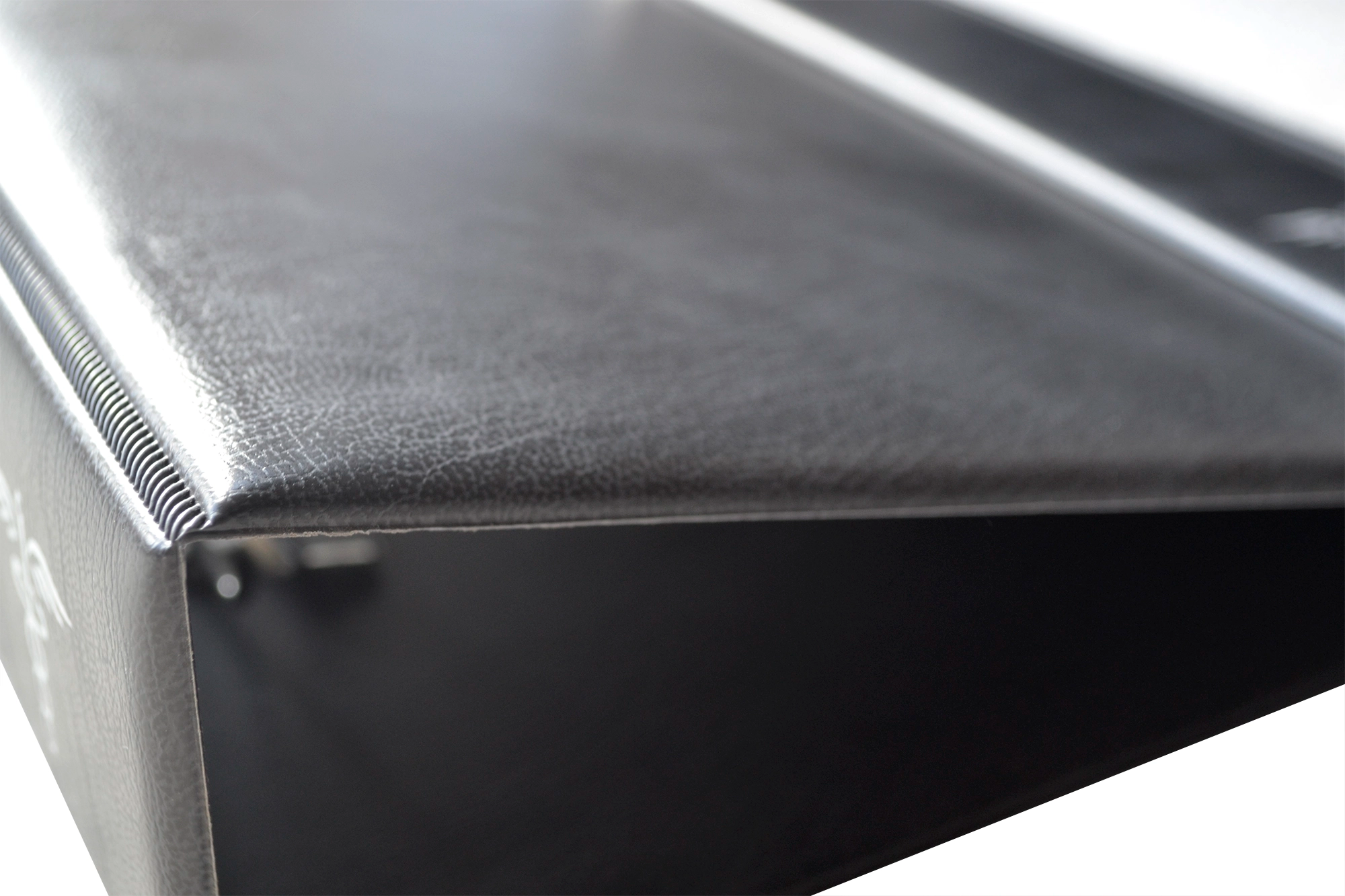

Custom Ring Binders

Optimise document management with our specialised ring binder creation service. We offer precision craftsmanship, high-quality materials, and customisable features for a professional and tailored organisational solution.

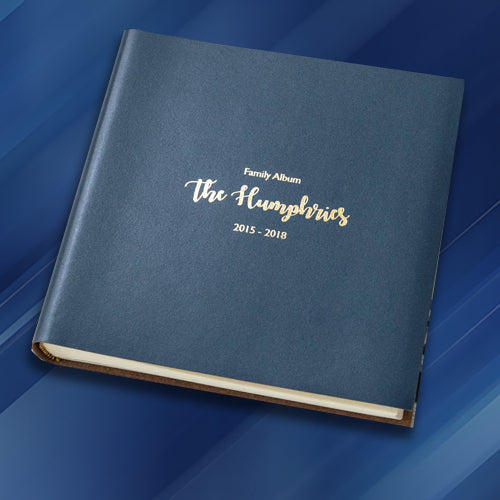

Product Packaging Solutions

Transform your Product Presentation with our Custom Packaging Design and Production Services.

Know What You're Looking For?

EXPLORE OUR RANGE OF OFF THE SHELF PRODUCTS

Die-cut Foam Inserts

Crafted through precision cutting techniques, these inserts are tailored to fit the contours of specific items, ensuring a snug and secure fit. Whether used for delicate electronics, precision tools, or intricate components, die-cut foam inserts provide a cushioned environment that guards against impact, scratches, and other forms of damage during storage or transport.